Synthetic graphite powder (GPC) is also called artificial graphite|artificial graphite powder. Generally, we use this name to distinguish it from natural graphite powder. Graphite powder is produced when processing graphite electrode as its by-product. In addition, graphite powder can also be obtained by calcining petroleum coke powder at a certain temperature and then undergoes graphitization. Graphite powder has superior performance and wide range of uses. It also has various sources, since every graphite product can be processed into graphite powder.

Artificial graphite|artificial graphite powder (GPC) has high purity, excellent lubricating property and strong electrical conductivity, so it is used as carburants in most cases to improve the carbon content of products for steel-making, reduction gears and casting. At the same time, graphite powder is widely used in the fire protection industry. Sometimes, it will be used as batteries or brake linings.

Unique physical characteristics of graphite powder (GPC): ● Relatively strong electrical & thermal conductivity

● High purity & high crystalline structure

● Relatively strong stability (Carbon molecules remain unchanged at high temperatures)

● High degree of lubrication

We have more than 16 years of experience in graphite material production and are able to provide high quality graphite powder with different granularity. The physical and chemical indexes of our graphite powder exceed the common indexes of the industry by 20 %. A special graphite powder manufacturing workshop is established to provide customers the high-purity, ordinary and ultra-fine particle graphite powders with leading graphite powder processing technologies and superior cost performance.

Artificial graphite|artificial graphite powder (GPC) has high purity, excellent lubricating property and strong electrical conductivity, so it is used as carburants in most cases to improve the carbon content of products for steel-making, reduction gears and casting. At the same time, graphite powder is widely used in the fire protection industry. Sometimes, it will be used as batteries or brake linings.

Unique physical characteristics of graphite powder (GPC): ● Relatively strong electrical & thermal conductivity

● High purity & high crystalline structure

● Relatively strong stability (Carbon molecules remain unchanged at high temperatures)

● High degree of lubrication

We have more than 16 years of experience in graphite material production and are able to provide high quality graphite powder with different granularity. The physical and chemical indexes of our graphite powder exceed the common indexes of the industry by 20 %. A special graphite powder manufacturing workshop is established to provide customers the high-purity, ordinary and ultra-fine particle graphite powders with leading graphite powder processing technologies and superior cost performance.

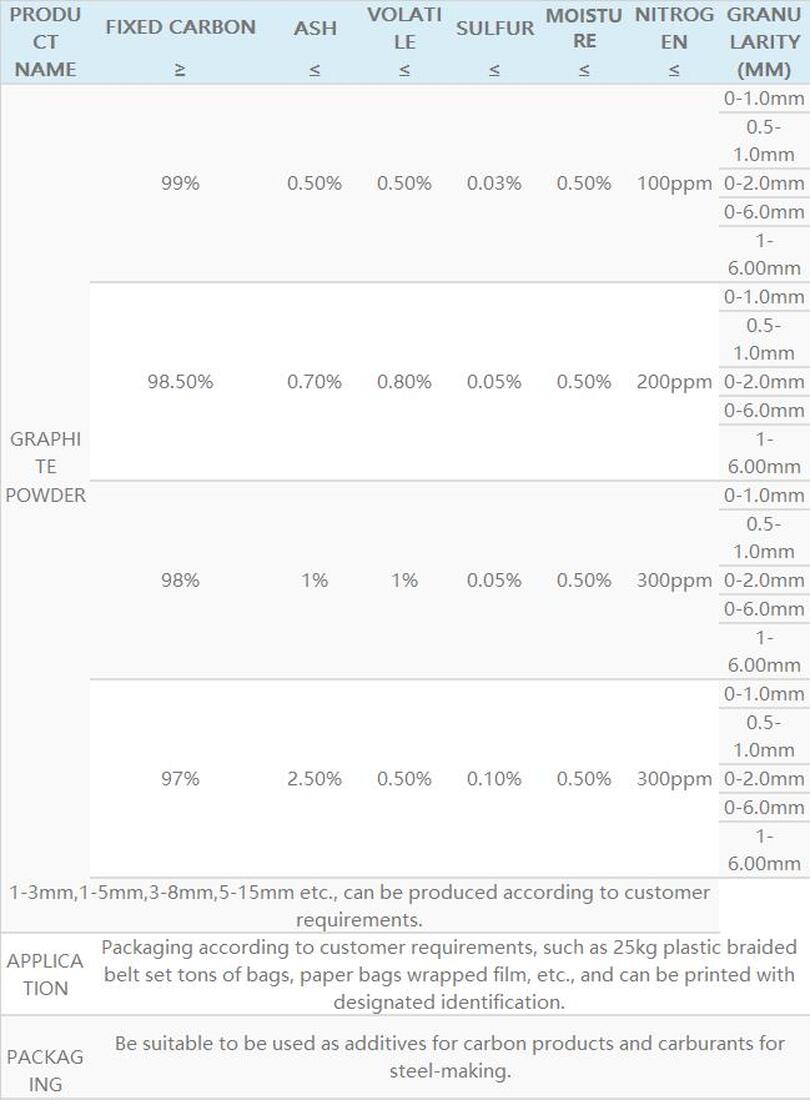

Processing specification of artificial graphite powder

Carbon content: 98-99.9

Granularity: 1/4---5 mm

Application industry of graphite powder

Carbon content: 98-99.9

Granularity: 1/4---5 mm

Application industry of graphite powder

- Lubricating material

- Energy industry

- Metallurgy

- Electrical industry

- Carbon brush industry

- Thread components

- Drilling equipment

- Rubber and polymer composites

- Packaging box sealing industry