The difference between high power graphite electrode and ultra high power graphite electrode5/8/2022 The difference between high power graphite electrode and ultra high power graphite electrode

Linyi city high power graphite electrode and ultra high power graphite electrode difference lies in: graphite is mainly used for (1) arc furnace (2) arc furnace (3) for the preparation of special-shaped graphite products resistance furnace (4).Graphite electrode billet can also be used to process various special shape graphite products, such as crucible, mold, container and heater.Graphite has good characteristics, so our company mainly produces graphite electrode, graphite products and graphite processing graphite foreign body.Our products reach the national qualified products and are well received by the majority of manufacturers and business partners.Here, we hope to build a commercial bridge with manufacturers from all walks of life.The difference between high power graphite electrode and ultra high power graphite electrode is mainly used to produce industrial silicon and yellow phosphorus.Its characteristic is that the lower part of the conductive electrode is buried in the charge layer, forming an arc in the charge layer, using the heat energy generated by the resistance of the charge itself to heat the charge, which requires high current density ore.The furnace needs graphite electrodes.For example, graphite electrodes consume about 100 kg per ton of silicon production and about 40 kg per ton of yellow phosphorus production.1) oil-impregnated graphite.Graphite materials should be soaked in oil for tens of hours before mechanical processing, so that the oil can penetrate into graphite materials, so that the fly ash will not fly out in the process of mechanical processing, and obtain a smooth surface.

0 Comments

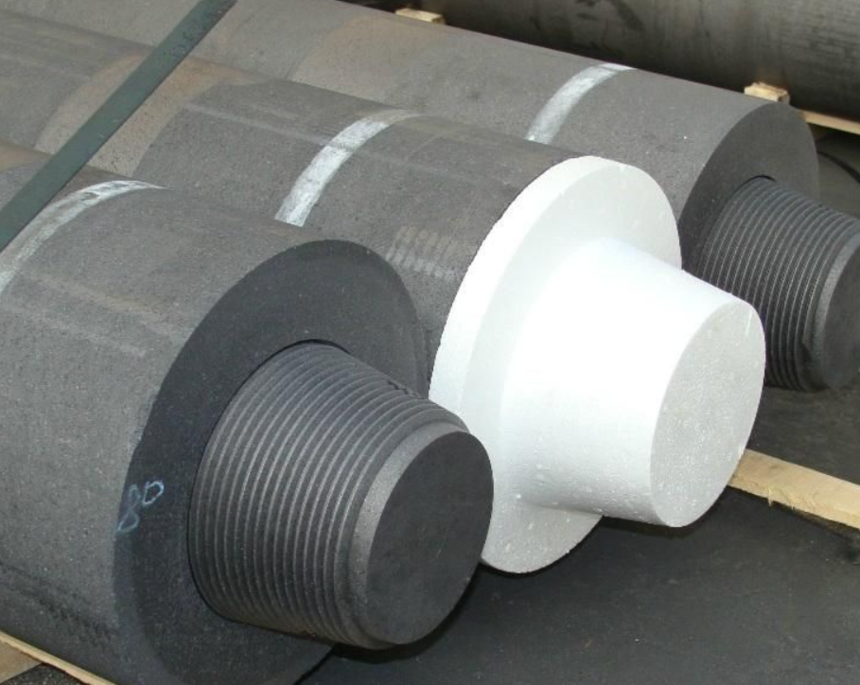

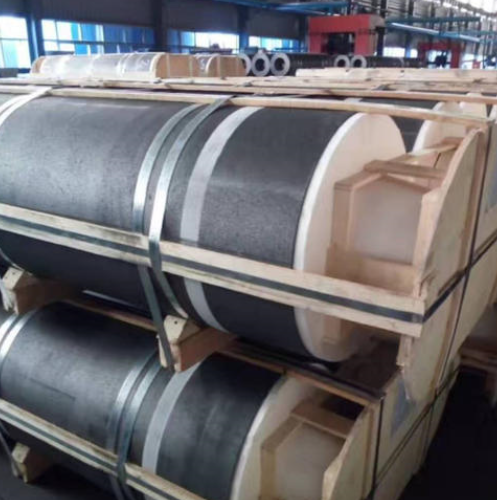

1. Correct clamping position of electrode holder The electrode holder should not be clamped at the connection between the electrode and the electrode threaded hole.Sandwiched between white wires at each end of the electrode.At the same time, before clamping the electrode with the clamping device, the surface of the electrode and the clamping device is blown clean with compressed air to ensure the good conduction of current and heat flow between the electrode and the clamping device, to prevent damage to the clamping device due to arc, so as to prolong the service life of the cage limit. 2. What are the measures to reduce the oxidation consumption of eAF electrode? (1) Reduce the oxidation consumption around the electrode, strengthen the sealing of the furnace, reduce the air intrusion into the furnace, minimize the exposure time of the red hot electrode outside the furnace, and standardize the oxygen blowing operation.(2) For smelting furnace, if conditions permit, spray cooling technology can effectively reduce electrode side oxidation consumption.(3) The oxidation resistance of the electrode body can be improved by spraying antioxidant on the electrode surface in the steel plant or by using antioxidant impregnation technology before the electrode leaves the plant. 3. What is the influence of electrode phase sequence on the use of electrode? In the process of electric arc furnace (EAF) steelmaking, the jumping phenomenon of positive and negative phase sequence is very important.If the electrode phase sequence is clockwise, the electrode will become loose after being energized for a period of time, which is easy to cause the electrode to become loose or the joint to break.The correct electrode phase sequence should be counterclockwise so that the electrodes are connected more and more tightly during use. 4. Why should the phase electrode be aligned with the top hole of the furnace cover when eAF steelmaking? The electrode column should be aligned with the top hole of the furnace cover.The electrode column should avoid friction with the furnace cover.Otherwise, friction with the cover during lifting and lifting will cause the cover to squeeze and break the electrode.For AC furnaces, the three-phase electrode column should be kept parallel as far as possible. 5. How to apply torque when tightening the electrode?

When tightening the electrode, the torque applied should be appropriate and the operation should be continuous.If the torque is too small, it will lead to loose joints;If the torque is too high, the electrode joint hole will crack.Use special electrode tightening tools when tightening.Don't twist it too tight or too loose.If there is a gap in the end contact after tightening, it must be removed and cleaned before tightening again. |

|

Hebei Shitu New Material Technology CO., LTD

|

|

RSS Feed

RSS Feed