The difference between high power graphite electrode and ultra high power graphite electrode5/8/2022 The difference between high power graphite electrode and ultra high power graphite electrode

Linyi city high power graphite electrode and ultra high power graphite electrode difference lies in: graphite is mainly used for (1) arc furnace (2) arc furnace (3) for the preparation of special-shaped graphite products resistance furnace (4).Graphite electrode billet can also be used to process various special shape graphite products, such as crucible, mold, container and heater.Graphite has good characteristics, so our company mainly produces graphite electrode, graphite products and graphite processing graphite foreign body.Our products reach the national qualified products and are well received by the majority of manufacturers and business partners.Here, we hope to build a commercial bridge with manufacturers from all walks of life.The difference between high power graphite electrode and ultra high power graphite electrode is mainly used to produce industrial silicon and yellow phosphorus.Its characteristic is that the lower part of the conductive electrode is buried in the charge layer, forming an arc in the charge layer, using the heat energy generated by the resistance of the charge itself to heat the charge, which requires high current density ore.The furnace needs graphite electrodes.For example, graphite electrodes consume about 100 kg per ton of silicon production and about 40 kg per ton of yellow phosphorus production.1) oil-impregnated graphite.Graphite materials should be soaked in oil for tens of hours before mechanical processing, so that the oil can penetrate into graphite materials, so that the fly ash will not fly out in the process of mechanical processing, and obtain a smooth surface.

0 Comments

1. Correct clamping position of electrode holder The electrode holder should not be clamped at the connection between the electrode and the electrode threaded hole.Sandwiched between white wires at each end of the electrode.At the same time, before clamping the electrode with the clamping device, the surface of the electrode and the clamping device is blown clean with compressed air to ensure the good conduction of current and heat flow between the electrode and the clamping device, to prevent damage to the clamping device due to arc, so as to prolong the service life of the cage limit. 2. What are the measures to reduce the oxidation consumption of eAF electrode? (1) Reduce the oxidation consumption around the electrode, strengthen the sealing of the furnace, reduce the air intrusion into the furnace, minimize the exposure time of the red hot electrode outside the furnace, and standardize the oxygen blowing operation.(2) For smelting furnace, if conditions permit, spray cooling technology can effectively reduce electrode side oxidation consumption.(3) The oxidation resistance of the electrode body can be improved by spraying antioxidant on the electrode surface in the steel plant or by using antioxidant impregnation technology before the electrode leaves the plant. 3. What is the influence of electrode phase sequence on the use of electrode? In the process of electric arc furnace (EAF) steelmaking, the jumping phenomenon of positive and negative phase sequence is very important.If the electrode phase sequence is clockwise, the electrode will become loose after being energized for a period of time, which is easy to cause the electrode to become loose or the joint to break.The correct electrode phase sequence should be counterclockwise so that the electrodes are connected more and more tightly during use. 4. Why should the phase electrode be aligned with the top hole of the furnace cover when eAF steelmaking? The electrode column should be aligned with the top hole of the furnace cover.The electrode column should avoid friction with the furnace cover.Otherwise, friction with the cover during lifting and lifting will cause the cover to squeeze and break the electrode.For AC furnaces, the three-phase electrode column should be kept parallel as far as possible. 5. How to apply torque when tightening the electrode?

When tightening the electrode, the torque applied should be appropriate and the operation should be continuous.If the torque is too small, it will lead to loose joints;If the torque is too high, the electrode joint hole will crack.Use special electrode tightening tools when tightening.Don't twist it too tight or too loose.If there is a gap in the end contact after tightening, it must be removed and cleaned before tightening again. Carbon products can be divided into graphite electrode, carbon block, graphite anode, carbon electrode, paste, electric carbon, carbon fiber, special graphite, graphite heat exchanger and so on. According to the allowed current density, graphite electrode can be divided into ordinary power graphite electrode, high power graphite electrode and ultra-high power graphite electrode. The carbon block can be divided into blast furnace carbon block, aluminum carbon block, electric furnace carbon block. According to the processing depth, carbon products can be divided into carbon products, graphite products, carbon fiber and graphite fiber.According to the different raw materials and production process, carbon products can be divided into graphite products, carbon products, carbon fiber, special graphite products.Carbon products can be divided into multi-ash products and low-ash products according to ash content (ash content less than 1%). China's national and ministerial technical standards for carbon products are classified according to their different uses and production processes.This classification method basically reflects the different uses and different production techniques of products, and is also convenient for accounting.The following describes the classification and description of carbon products. Carbon and graphite products A、Graphite electrode is mainly made of petroleum coke and needle coke as raw materials, using calcination, proportion, kneading, pressing, roasting, graphitization, mechanical processing and other binder.They are conductors that release electrical energy in the form of electric arcs to heat and melt furnace materials.According to its quality index can be divided into ordinary power, high power and ultra high power.Graphite electrodes include: (1) General power graphite electrode.The graphite electrode with current density less than 17A/cm 2 can be used in ordinary electric furnace such as steelmaking, ironmaking and smelting. (2) Oxidation resistant coated graphite electrode.The graphite electrode, coated with an oxidation protection, forms a conductive layer that conducts electricity and resists high-temperature oxidation, reducing the cost of the electrode during steelmaking. (3) High-power graphite electrode.Graphite electrodes with allowable current density of 2 / cm are mainly used in high-power electric arc furnaces for steelmaking. (4) Ultra-high power graphite electrode.Graphite electrodes with current densities greater than 25A/cm 2 are allowed.Mainly used in ultra-high power electric arc furnace for steelmaking. B、 graphite anode Mainly with petroleum coke as raw material, by calcination, batching, kneading, pressing, roasting, impregnation, graphitization, mechanical processing and become binder.Conductive anode used in electrolysis equipment in electrochemical industry.Include: (1) a variety of chemical applications of the anode plate. (2) various anodes. (3) special graphite Mainly with high quality petroleum coke as raw materials, raw materials, ingredients, mixing, pressing, crushing, remixing, molding, multiple roasting, multiple impregnation, purification, graphitization, mechanical processing as binder.It is widely used in aerospace, electronics and nuclear industries. It includes spectrum pure graphite, high purity, high strength, high density and pyrolytic graphite. (4) graphite heat exchanger C、The artificial graphite is processed into the desired shape, and then impregnated and cured with resin to make impervious graphite products for heat exchange.It is a heat exchanger based on artificial impervious graphite, mainly used in chemical industry.Include: (1) plug hole heat exchanger; (2) radial heat exchanger; (3) falling film heat exchanger; (4) tube heat exchanger. (5) Carbon electrode D、Anthracite, metallurgical coke (or petroleum coke) and other carbon materials as raw materials, the use of *** as binder.The conductive electrode is made of ***, without graphitization.Not suitable for electric furnace smelting high grade alloy steel.Include: (l) Dusty electrodes (electrodes made of anthracite, metallurgical coke and bituminous coke); (2) Recovery electrodes (electrodes made of artificial graphite and natural graphite); (3) carbon resistance strip (carbon grid brick); (4) carbon anode (petroleum coke pre-baked anode); (5) Calcination of electrode billet. (6) carbon blocks Anthracite and metallurgical coke as the main raw material, *** as binder.It is mainly composed of raw material preparation, batching, mixing, molding, roasting, processing and other processes.Among them, carbon block of blast furnace is used as high temperature and corrosion resistant material of blast furnace lining, while bottom carbon block, side carbon block and electric furnace carbon block are used in aluminum electrolytic cell and ferroalloy furnace.Include: (1) blast furnace carbon block; (2) aluminum groove carbon block (bottom carbon block and side carbon block); (3) electric furnace carbon block. (4) Carbon paste The main raw materials are petroleum coke, anthracite and metallurgical coke, and the binder is ***.Some are used as electrode paste for conducting electrodes in various continuous self-baking furnaces;Some are used as anode paste for conductive anode in continuous self-baking aluminum cell;Some are used as fillers in blast furnace masonry and as thick and thin joint paste in refractory mud.Although the use of self-baked charcoal block in blast furnace is different, it is similar to the paste product in the production process and temporarily stuck in the paste product.Include: (1) anodic paste; (2) Electrode paste (including standard and non-standard electrode paste); (3) alkali paste (containing less ash, less ash); (4) Closed slurry (containing less ash and less ash); (5) Other paste (including coarse seam paste, fine seam paste, self-baking carbon brick, etc.). (6) Non-standard carbon and graphite products This refers to various profiled carbon and graphite products made by further processing of carbon and graphite products.Including shovel-type anodes, production of anode and crucible, plate, bar, block and other special-shaped products of various specifications. (7) impervious graphite This refers to various graphite profiles made by impregnation and treatment of resins and various organic materials, including matrix blocks for heat exchangers. (8) Types of electrodeposition carbon products This refers to carbon rods, carbon brushes and other products. The carbon fiber

It includes a variety of carbon fiber, graphite fiber, pre-oxidation wire, carbon cloth, carbon tape, carbon rope, carbon felt and its composite materials.Carbon fiber is a fiber that contains more than 93 percent carbon.Carbonization of polypropylene fiber, viscose fiber and asphalt fiber.Heat resistant fiber, carbide fiber and graphite fiber can be made from low to high heat treatment temperature. Graphite products are still widely used in industry and are widely used in the following fields:

1.As refractory material: graphite and its products have the characteristics of high temperature resistance and high strength.Graphite crucible is mainly used in metallurgical industry.Graphite is commonly used as a protective agent for ingot and lining of metallurgical furnace for steelmaking. 2.Conductive materials: in the electrical industry, used to manufacture graphite electrode, carbon brush, carbon rod, carbon tube, mercury rectifier anode, graphite gasket, telephone accessories, television picture tube coating, etc. 3.Graphite as wear-resisting and lubricating materials, often used as a lubricant in the machinery industry.Lubricating oil can not be used under high speed, high temperature and high pressure.Graphite wear-resistant material at 200~2000℃ without lubricating oil can achieve high-speed sliding.Many devices are used to deliver corrosive media, and graphite electrode manufacturers use the material extensively for piston cups, seals and bearings.No lubricant is required during operation.Graphite emulsion is also a good lubricant for many metal processing (wire drawing, tube drawing). 4.Graphite has good chemical stability.The specially processed graphite has the characteristics of corrosion resistance, good thermal conductivity and low permeability.Widely used in heat exchanger, reaction tank, condenser, combustion tower, absorption tower, cooler, heater, filter, pump and other equipment.Widely used in petrochemical, hydrometallurgy, acid and alkali production, synthetic fiber, papermaking and other industrial sectors, can save a lot of metal materials. Click here to ediThese two materials are different.Graphite electrode is made of petroleum coke and needle coke as raw materials and coal pitch as binder by calcination, batching, kneading, pressing, roasting, graphitization and mechanical processing.They are conductors that release electrical energy in the form of electric arcs to heat and melt furnace materials.According to its quality index, can be divided into ordinary power, high power and ultra high power.Graphite rod is a kind of nonmetal products.As a necessary welding consumable in the process of carbon arc gouging, carbon and graphite are extruded and formed with appropriate binder. After being rotated at 2200℃, a layer of copper is roasted. It has the characteristics of high temperature resistance, good electrical conductivity and not easy to break.Suitable for cutting metal into desired shape.t.

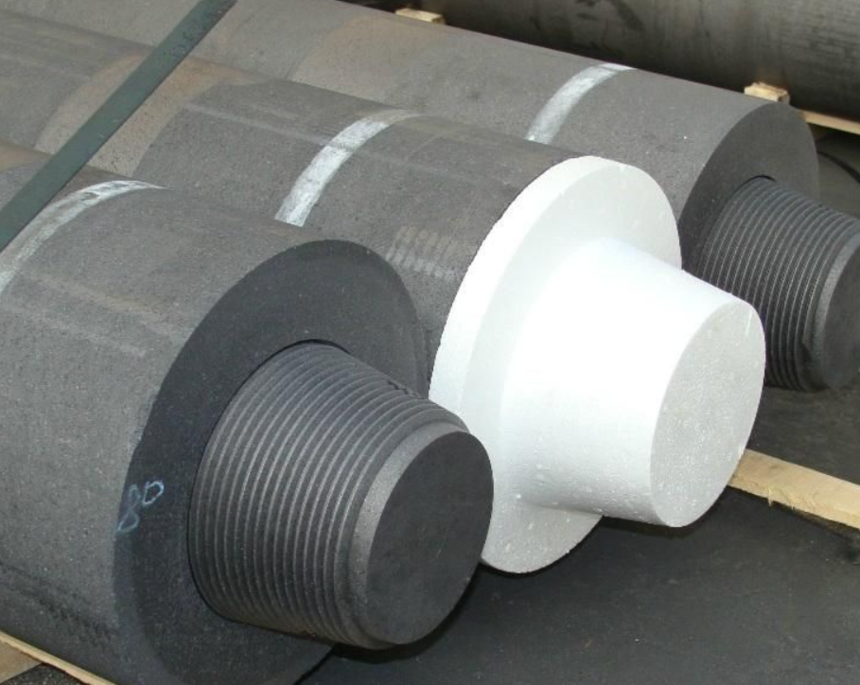

The breakage of the graphite electrode is partly due to its handling and control, but the quality of the electrode itself is also a determining factor. (1) Causes of nipple fracture of graphite electrode: The nipple of graphite electrode plays a key role in the connection of electrode in steelmaking. The quality of nipple is directly related to the application of electrode in steelmaking.The connection area formed by graphite electrode and nipple is a complex part with large electrical, thermal and mechanical loads, and is also a common part of fracture.According to relevant data, more than 80% electrode accidents in electric furnace steelmaking are caused by nipple breakage or loosening.In terms of the quality of the nipple itself, the main reasons for nipple fracture are: small volume density, low strength, easy to fracture when using;High resistivity, the joint temperature rises quickly when energized, resulting in large thermal stress at the electrode nipple.Increased risk of nipple breakage;Fracture strength is not enough;Internal crack joint mixed with finished nipple, forming a major hidden trouble;Nipple and electrode machining accuracy index is not reasonable match, easy to fracture. (2) Causes of electrode fracture

In general, the probability of electrode fracture is low.The main causes of electrode fracture are: screw hole quality defects;Insufficient electrode volume density and strength;The index of electrode and nipple do not match, and the machining accuracy is not high.The deep crack at the electrical end is caused by the unqualified quality of the threaded hole.Thermal shock resistance of electrode.In addition, electrodes with no internal transverse cracks detected in the finished product pose a significant risk of breakage. 1.CNC machining speed, high cutting performance, easy edge cuttingGraphite can be machined 3-5 times faster than copper electrodes.The finishing speed is particularly outstanding and the intensity is very high.For ultra-high (50-90mm) and ultra-thin (0.2-0.5mm) electrodes, it is not easy to deform during machining.Moreover, in many cases, the product needs to have a good particle surface effect, which requires that the whole electrode be made as far as possible, with various invisible cleaning angles for the whole electrode.Because of the properties of graphite, this problem is easily solved, with the number of electrodes greatly reduced, but not the copper electrode. 2.Light weight, low cost In the manufacturing cost of a set of die, the CNC machining time, EDM machining time and electrode loss account for the vast majority of the total cost, which is determined by the electrode material itself.Compared with copper, the machining speed and edM speed of graphite is 3-5 times that of copper.At the same time, with the characteristics of low wear and manufacturing all-anode graphite electrode can reduce the number of electrodes, and also reduce the consumption of electrodes and processing time.These can greatly reduce the mold production cost. 3.Rapid edM forming, small thermal expansion, low loss Because graphite conducts electricity better than copper, it discharges three to five times faster than copper.And the discharge can withstand a larger current, more conducive to rough machining.At the same time, the weight of graphite is 1/5 of copper in the same volume, which greatly reduces the load of EDM.It has great advantages in making large electrodes and integral positive electrodes.The sublimation temperature of graphite is 4200℃, which is 3 ~ 4 times that of copper (1100℃ for copper).At high temperature, the deformation is very small (1/3~1/5 of copper under the same electrical conditions), and does not soften.It can transfer the discharge energy to the workpiece efficiently and cheaply.With the increase of graphite strength at high temperature, the discharge loss (graphite loss is 1/4 of copper) can be effectively reduced to ensure the processing quality. In recent years, with the introduction of precision die and high-efficiency die (die cycle is shorter and shorter), people put forward higher and higher requirements for die manufacturing.Due to the limitation of various conditions of copper electrode itself, it can not meet the development requirements of mold industry.As electrode material for EDM, graphite has the advantages of strong cutting ability, light weight, fast shaping, small expansion rate, small loss and easy dressing, etc., and has been widely used in die industry.Replacement of the copper electrode is unavoidable.A. Basic principle of discharge

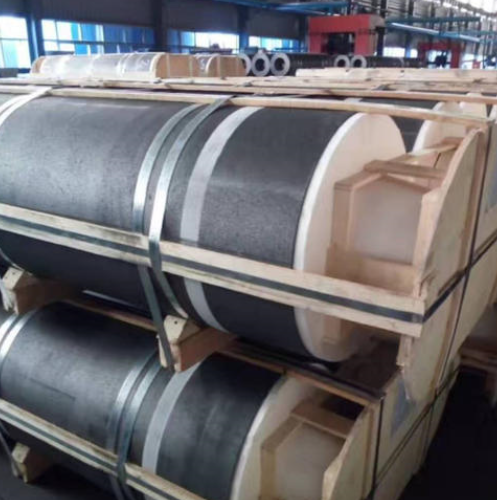

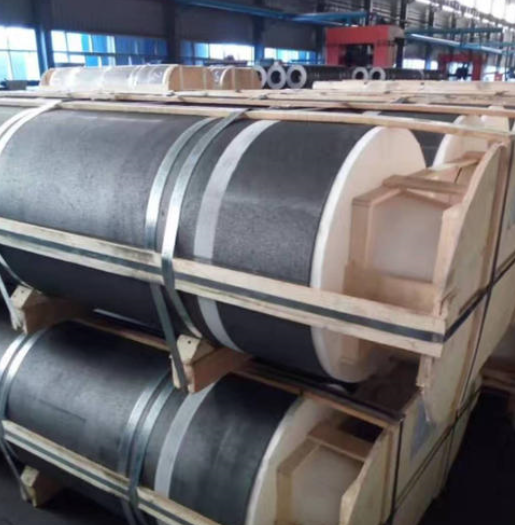

1.The electrodes are close to the workpiece surface, the workpiece surface generates high pressure on each other, and the electrolyte begins to ionize into a plasma energy column. 2.After the energy column is formed, the electrode transmits a low voltage to the workpiece surface. 3.When electrons flow between the electrodes, they generate extremely high thermal energy, resulting in an electrochemical reaction that creates bubbles of hydrogen gas. 4.During the discharge, the material under the energy column is in a molten state. 5.At rest, the hydrogen bubble implodes, and this part processes the liquid for gasification.The melted material is cooled, solidified and released through the surrounding treatment fluid. At the end of the discharge cycle, a cavity is formed on the workpiece due to the removal of the material.This is the smallest unit in EDM, followed by the next discharge cycle. B, processing characteristics 1.Large electrode or rough machining efficiency is significant 2.The advantages of small electrodes or finishing are not obvious 3.The electrical parameters are completely different from those of copper electrodes 4.The sheet electrode does not deform during discharge 5.Sensitive to current easily cause abnormal discharge 6.The low losses are due to carbon bonding 7.Surface roughness is not up to the high standard of copper electrode 1, what are the characteristics of needle coke? Needle coke is a kind of high quality carbon raw material, divided into coal series and oil series.The focal surface of needle has obvious stripes.When it breaks, most of it is in long, needle-like pieces.The fiber structure can be observed under the microscope, so it is called needle coke.Needle coke tends to graphitize at high temperatures above 2000 degrees.The needle coke graphite electrode has low resistivity, high volume density and low thermal expansion coefficient.It is a necessary raw material for producing ultra-high power electrode and high power electrode.Needle coke is much more expensive than ordinary coke, the current price is about 5-8 times that of ordinary coke. 2. Will the vacuum system on the eAF affect electrode consumption? The fan used in the dust collection system generates a certain negative pressure during operation, which increases the flow of air around the red-hot electrode during the preparation of steel, thus increasing the oxidation consumption of the electrode.In the process of steelmaking, a good dust removal system not only keeps a good working environment, but also makes electrode consumption stable. 3. How to avoid the increase of electrode consumption in steelmaking process? In order to avoid the increase of electrode consumption in the process of steelmaking, the following measures should be taken :(1) according to the design requirements of electric furnace, keep good power supply state, power supply within the range of electrode current intensity.(2) Prevent the arc point from immerging into the molten pool.(3) Prevent electrode from immerging in steel liquid to increase carbon.(4) Spray cooling technology should be used for electrodes if conditions permit.(5) Set the correct exhaust system.(6) Use the correct oxygen blowing system. 4. How long does the production cycle of graphite electrode take? The production process and corresponding time of a batch of ultra-high power or high power graphite electrode are as follows: pressure electrode (3 days) - baking (25 days) - impregnation (4 days) - rebaking (15 days) - graphitization (10 days) - machining, quality inspection (2 days) - finished product packaging and delivery (1 day), I, E.Production lasts up to 60 days from feed to product delivery and 90 days for electrode joints because two soaks and three bakes are required. 5. What are the characteristics of the electrode produced in series graphitization furnace?

The development direction of graphitization furnace is internal heat series graphitization furnace.Because the current density of the connected column is the same, the resistivity difference of the electrode is very small.Second, within the string of graphitizing product on both ends of the resistivity is slightly lower than the middle (acheson graphitization furnace product resistivity is higher than the middle on both ends), beneficial to reduce the resistance of the joint, when users use slow joint overheating aglow phenomenon, make the concatenated graphitizing furnace electrode quality same as acheson furnace, electric arc furnace steelmaking is more suitable for production requirement. |

|

Hebei Shitu New Material Technology CO., LTD

|

|

RSS Feed

RSS Feed